Cleaning aluminium components after machining for a company from global automotive concern

Our client is part of a global automotive corporation. The company has many years of manufacturing experience, specialising in the production of components for passenger cars.

What did the customer require?

The customer needed support in cleaning aluminium parts after the machining process. We faced the challenge of designing a machine that cleans parts with complicated geometries. The project involved a complex, multi-stage cleaning process.

Specific client’s project requirements:

- Cycle time: 28 sec. per detail

- Cleanliness requirements: 600 µm for metallic particles

- Surface wettability: 34 mN/m

- Preparation of the system for automatic loading and unloading

- Stabilisation of the workpiece temperature for the leak measurement process

Solution implemented at the customer’s site

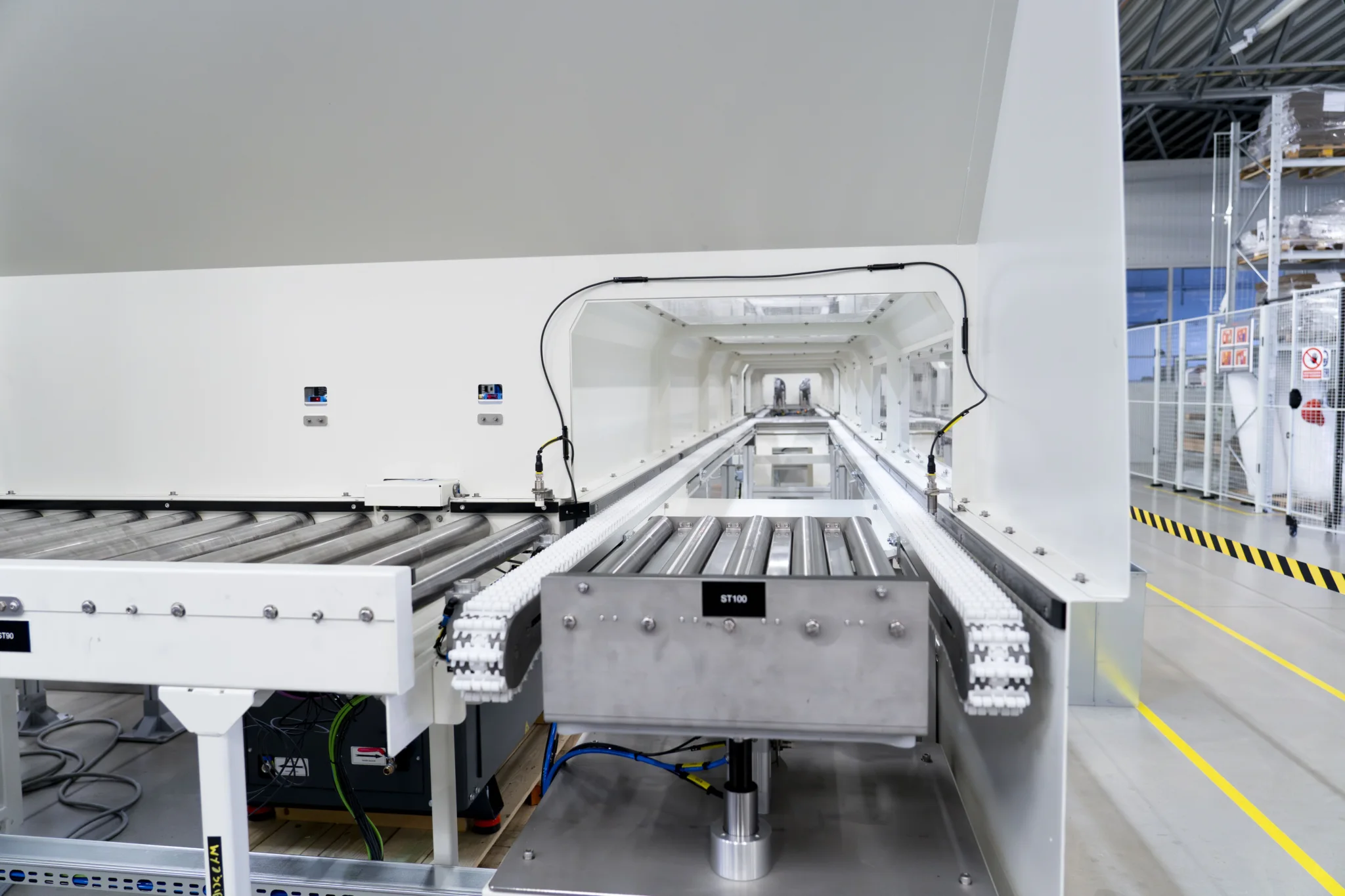

NOYEN recommended a machine from the NOYEN Expert T line – tunnel device, consisting of several sections that enable a complex washing process:

- Two types of cleaning to thoroughly remove particles and meet quality requirements

- Two-step rinsing with demineralised water

- SprayTech PRO System – our advanced solution for precision cleaning of parts with difficult geometries

- Two types of drying

- Stabilisation of the workpiece temperature

The machine was customised to the client’s needs in terms of the efficiency and quality of the process and the difficult geometry of the parts being cleaned. Their transport is carried out on pallets. One pallet can hold two workpieces, which have been suitably exposed to achieve the most effective cleaning process. The machine has been prepared for automation, but also has the possibility of manual loading and unloading. We have used a closed feeder circuit in the machine, which is controlled by an air-conditioned electrical cabinet with an energy meter.

What has the client gained from working with NOYEN?

- Cleaning machine developed for specific project requirements

- Cleaning process meeting the required cycle time – 28 sec. per detail and technical cleanliness standard – max. 600 µm for metallic particles

- Details cleaned according to the required degree of surface degreasing – 34 mN/m

- Possibility of handling two references

- System prepared for automatic loading and unloading

- Full technology selection and NOYEN support in the process

Nie ma rzeczy niemożliwych

Będzie łatwiej, kiedy powiesz nam, o co chodzi. Oszczędź sobie czasu i wykorzystaj Twoją bezpłatną konsultację. Nasz ekspert za darmo udzieli Ci porady.