More efficiency.

The same compact design.

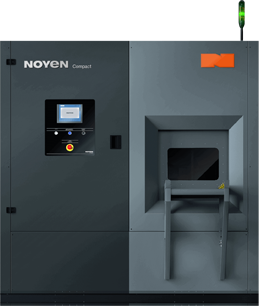

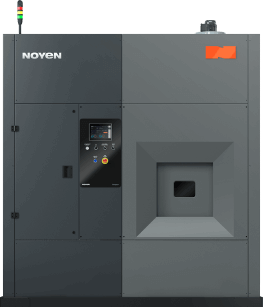

Meet

Compact 800

- Self-sufficient vapor separation system

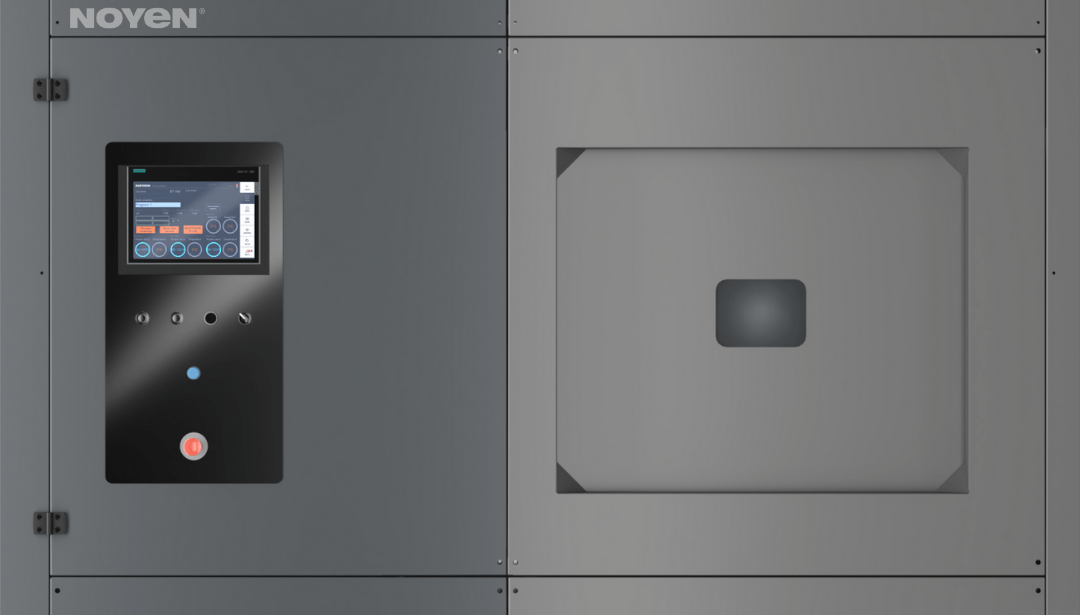

- Intuitive interface

- Load capacity up to 200 kg

- 8 bar spray pressure

- Colour lamp in chamber

Compact 800 cleans:

- shafts

- housings

- bearings

- sleeves

- rings

- flanges

- gear wheels

- rods

- steel and aluminum castings

- bolts, screws

- workpieces with difficult geometry

Advantages

Efficient cleaning – the Compact 800 effectively cleans parts made of various materials such as steel, aluminum, copper, brass, galvanized steel and stainless steel.

Compliance with cleanliness standards – enables both standard cleaning of parts for further manufacturing process and cleaning compliance, meeting cleaning standards up to 250 microns.

Facilitated loading – integration with a scissor loading table, making the process of loading workpieces into the machine easier.

Freely configurable cleaning program – customizable to meet individual requirements, ensuring optimal cleaning efficiency and quality.

Eco-friendly solution – easy liquid transfer between tanks, which minimizes waste and reduces operating costs.

Increased filter life – filter wear control, allowing for effective monitoring and replacement in a timely manner, ensuring continuous machine operation.

Tooling – to match different types of tools, providing cleaning versatility.

Industries

- Automotive

- Aerospace

- Regeneration

- Tool washing

- CNC machining

- Fabrication of small metal components

- Fabrication plants

- Foundries

- Grinding plant

Technical data

| External size [lenght x width x height] | 3800 x 2600 x 2950 mm |

| Loading height | 1040 mm |

| Basket size | 800 x 800 x 600 mm |

| Loading | 200 kg |

| Spraying pressure | 8 bar |

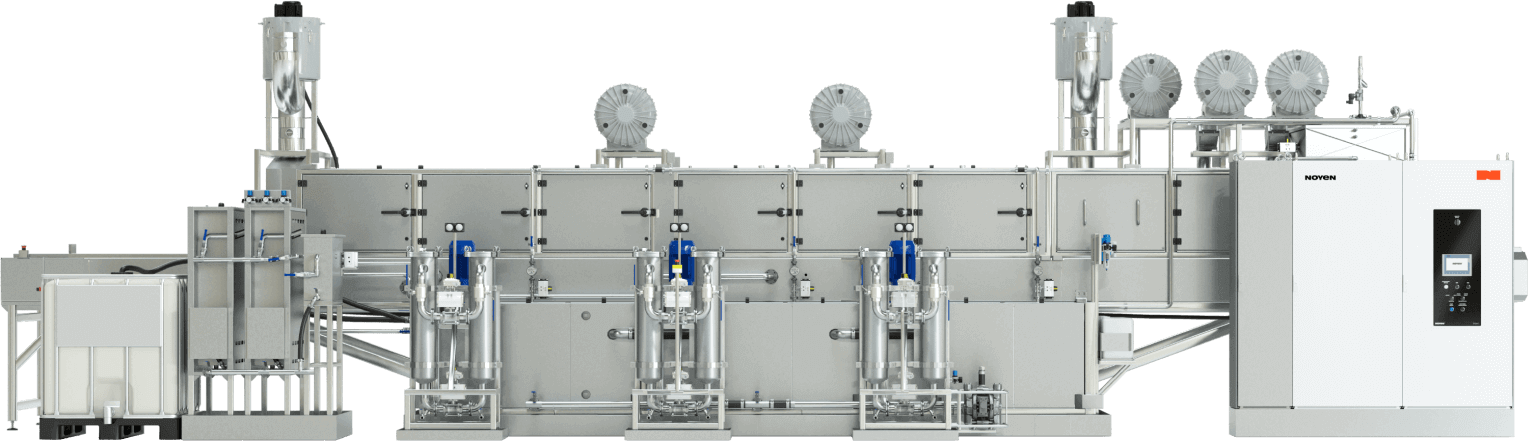

| Tank capacity | Total 3100 l |

| Water tanks | 2 |

| Baskets capacity | About 6 baskets per hour |

| Bath temperature | Max. 70°C |