Dry suction extraction system

The term of technical cleanliness relates to the level of particulate contamination, as well as the conditions under which components are manufactured and tested. There are a number of testing standards to determine whether the assumed cleanliness requirements have been met. The mentioned standards are used, among others, in the automotive industry. Depending on the type and purpose of the components, manufacturers follow internal cleanliness standards, which are based on the guidelines specified, inter alia, in VDA 19.1 and ISO 16232. Technical cleanliness requirements and the need to test components are increasingly common in other industries, such as the aerospace, electronics and medical industries.

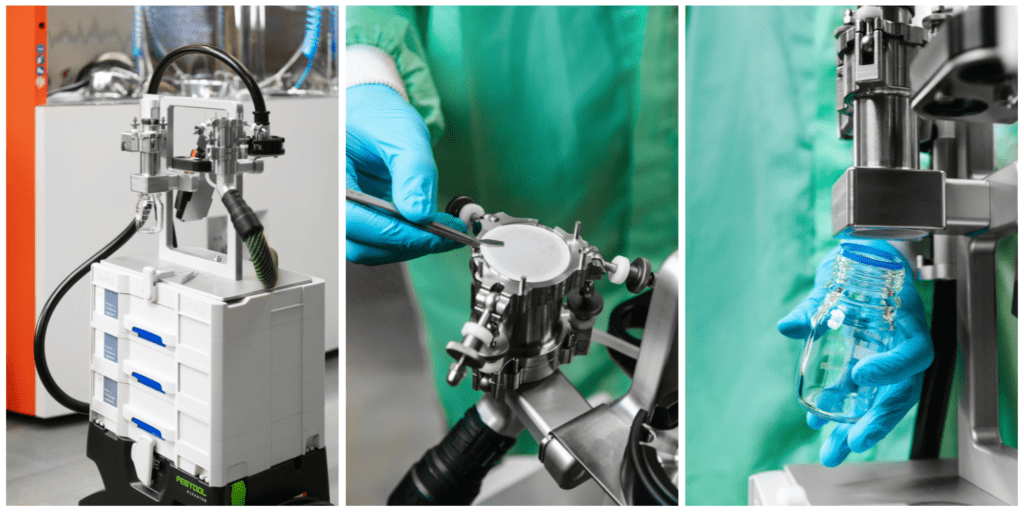

One of the latest solutions for determining technical cleanliness is a vacuum extraction system. It works by suction extraction of the particles to be analysed from the surfaces of components or specified areas using specially dedicated nozzles. The particles are extracted by vacuum and collected on a strainer. This solution is particularly useful in cases where traditional liquid extraction methods are insufficient or inappropriate, such as when analyzing PCBs or electronics. This system differs significantly from those used so far, providing new opportunities for technical cleanliness testing.

Advantages of the vacuum extraction system

- Reliable for large-size workpieces – the system allows extraction of contaminants from large surfaces, such as palletcontainers, KLT containers, trays

- Safe for tested components – the particular stages of the process do not endanger non-wet extractable components (e.g., electronics) that are not resistant to classically used extraction liquids, such as isoparaffins or isopropyl alcohol

- Time and media savings – there is no need for using liquid extraction media and drying the filter, which significantly shortens the entire process

- Easy transportation – the compact and mobile design of the device allows it to be used, for example, directly on the production hall. This makes it much easier to conduct research in a process environment.

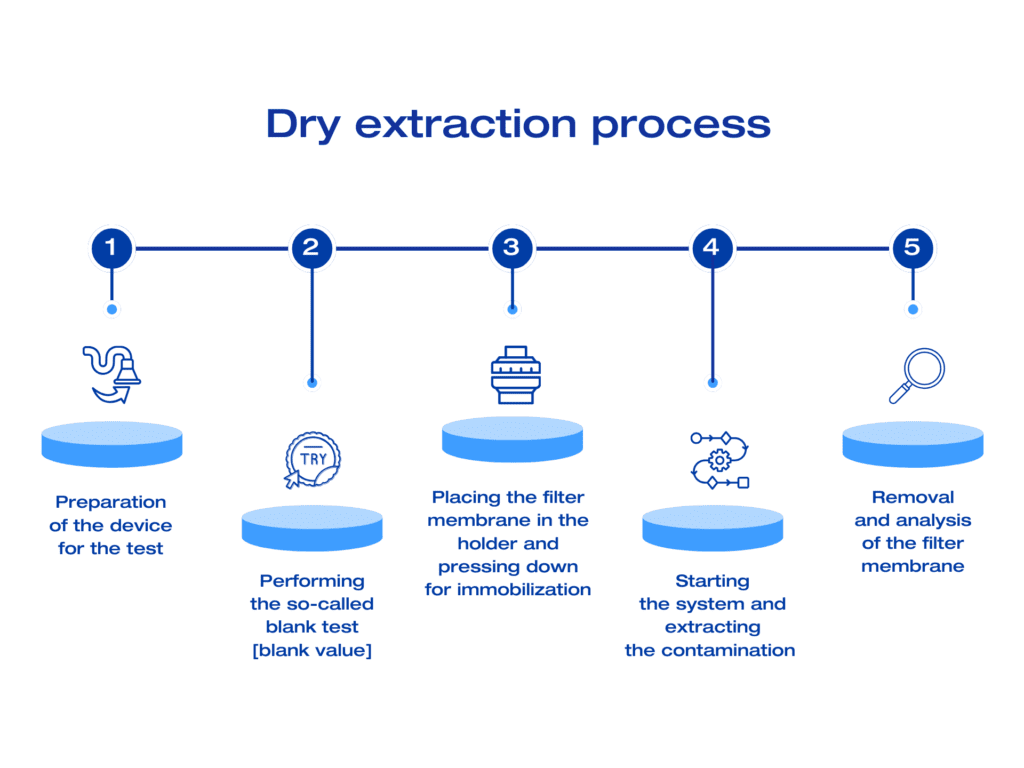

How does the dry extraction process work?

Where to use the vacuum extraction system?

The suction extraction system is used in a variety of industries: from automotive and production of electrical and electronic components, to the packaging industry. This allows to carry out an analysis of technical cleanliness on large-scale components, making it much easier to extract contaminants from their surfaces. It is an excellent complement to traditional wet extraction method.

NOYEN – industrial chemicals and machines manufacturer, which comprehensively meets the needs in the field of industrial cleaning, machine service, automation, laboratory tests and chemistry. Check out our wide range of cleaning devices and find out how NOYEN can support your business – contact our specialists.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.