Inter-operational cleaning of steel driveline components prior to quality control

Our regular customer is a leading supplier of driveline components to OEMs. Our cooperation started in 2017. Since then, we have delivered two devices to the customer for cleaning the final product before storage, while the latest implementation was the second inter-process cleaning project.

What did the client require?

The client needed a cleaning machine adapted to the production line for a new half-shaft project. After the machining process, the parts were contaminated with machining coolant and metallic particles. Before the next step – the dimensional tolerance measurement process, the parts had to be washed, degreased and thoroughly dried.

The customer’s requirements:

- Device integrated and adapted to the hall and production line layout

- Cleanliness level of 38 mN/m surface tension

- 12 different types od washed parts

- Short delivery time

Solution implemented at the client’s site

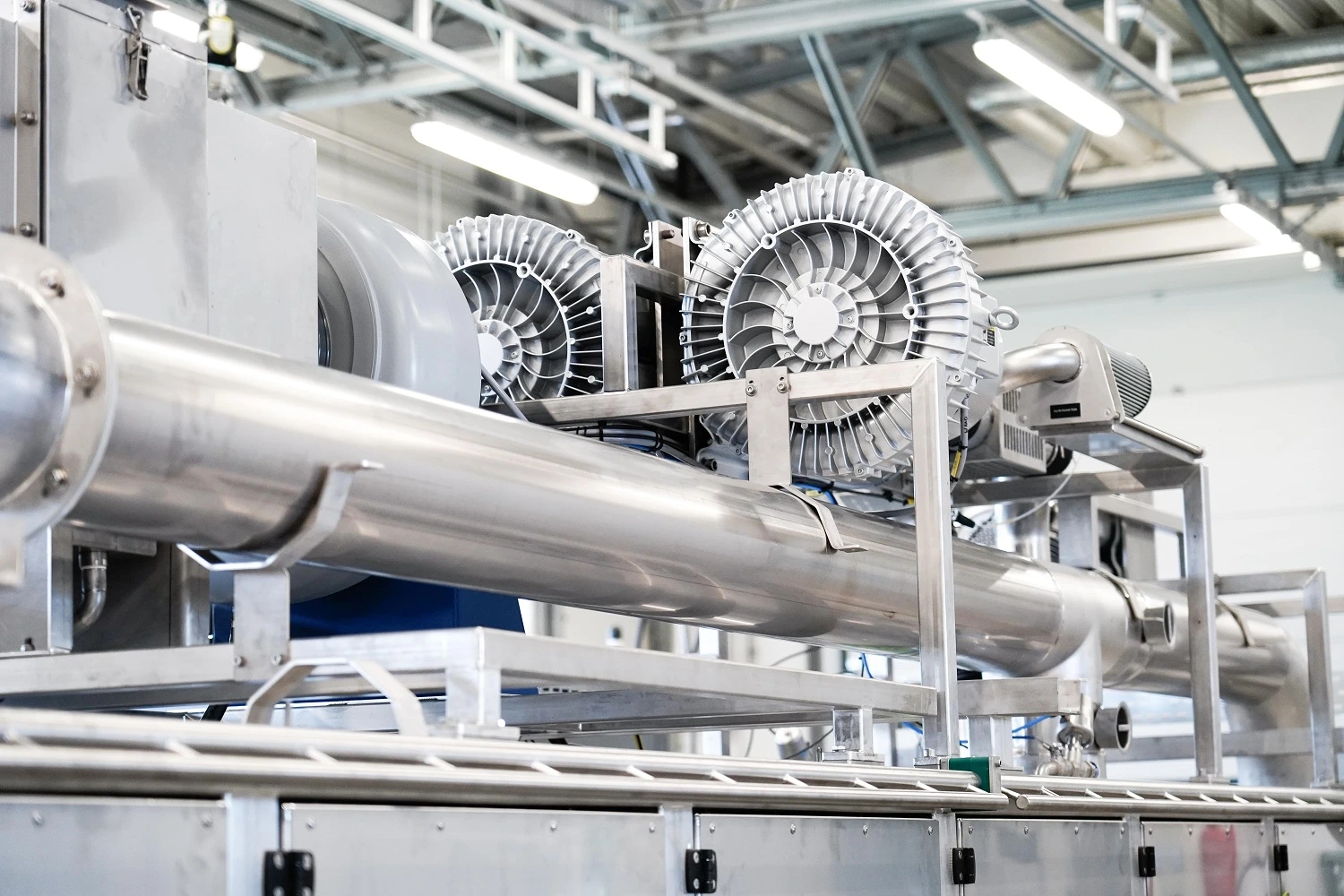

We proposed a NOYEN Expert T tunnel washer, consisting of functional zones:

- spray washing,

- spray rinsing with corrosion inhibitor

- drying

The machine was tailored to the customer’s needs in terms of layout, the dimensions of washed parts and the specified capacity – 16 seconds per 1 part.

The implemented solution met the requirements for cleaning efficiency and quality. One of the key parameters was the temperature of the workpiece at the end of the washing process. This could not exceed 30°C. The machine can be connected to the customer’s central media management system. The loading and unloading of the workpieces takes place automatically. This is another NOYEN machine that the customer owns, so the cost of servicing and the number of consumable parts is kept to a minimum.

What has the client gained from working with NOYEN?

- Tailor-made cleaning machine – adjusted to the specifics of the production line

- Device connected to a central bath management system

- Possibility of handling different part types and sizes

- Parts washed in accordance with the required level of surface degreasing

- Short lead time – delivery to the customer 4 months after the order

- Possibility of a fast and cost-effective maintenance service.

For the further information about industrial cleaning process, feel free to contact us! Our experts will prepare a solution perfectly tailored to your cleanliness requirements and your company business needs.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.