Inter-stage cleaning of piezoceramic tiles for a manufacturer of marine measuring equipment

Our new client from the maritime industry, providing technology for safe and sustainable ocean space exploration, designs, among other things, communication and navigation solutions.

What did the client require?

The client approached us with a request for a solution to remove dust from ceramic actuator elements of the echolocation system after the diamond disc cutting process. The customer needed to improve the product quality and achieve better resin housing adhesion to the component. We faced the challenge of cleaning very delicate pieces prone to mechanical damage.

Solution implemented at the client’s site

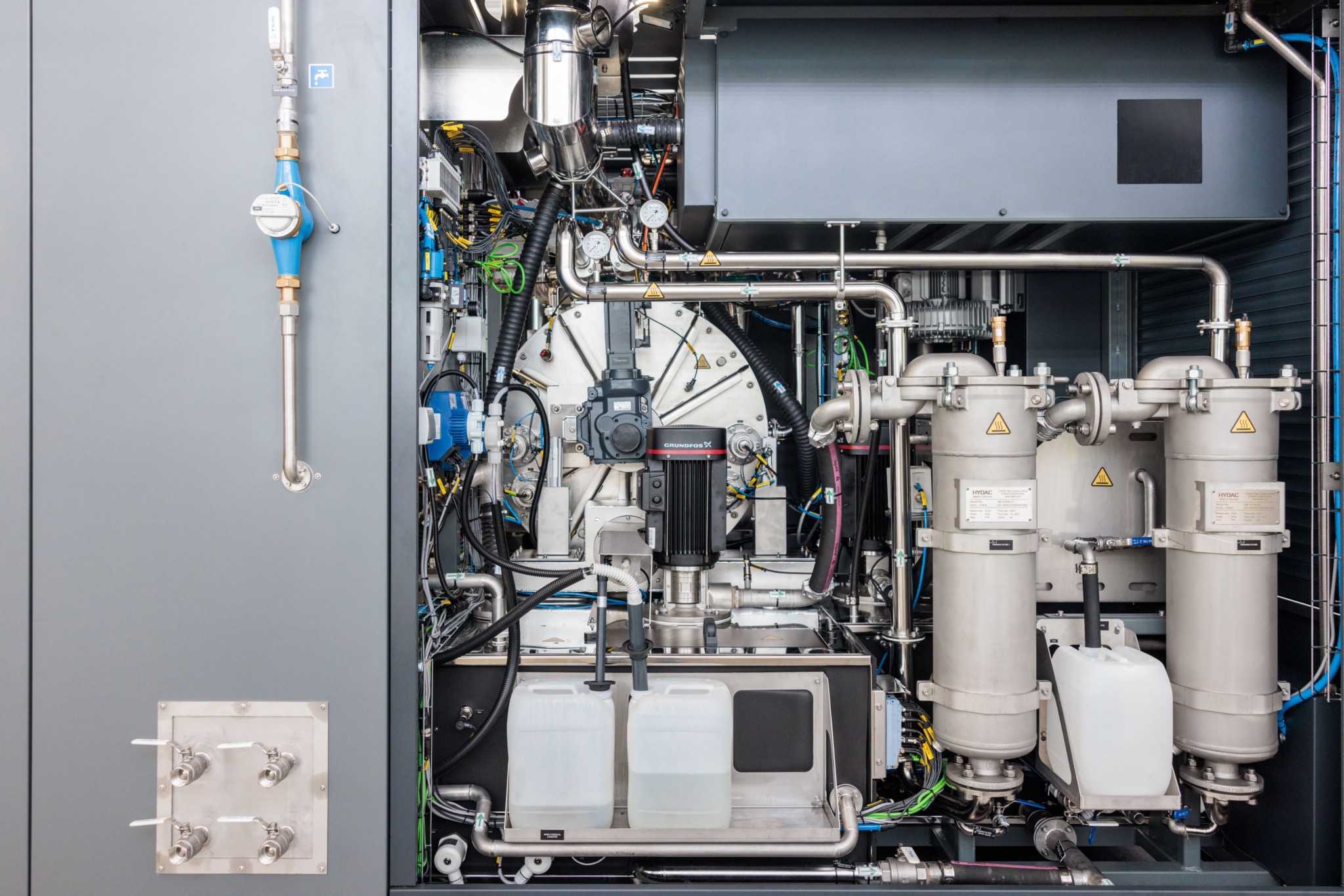

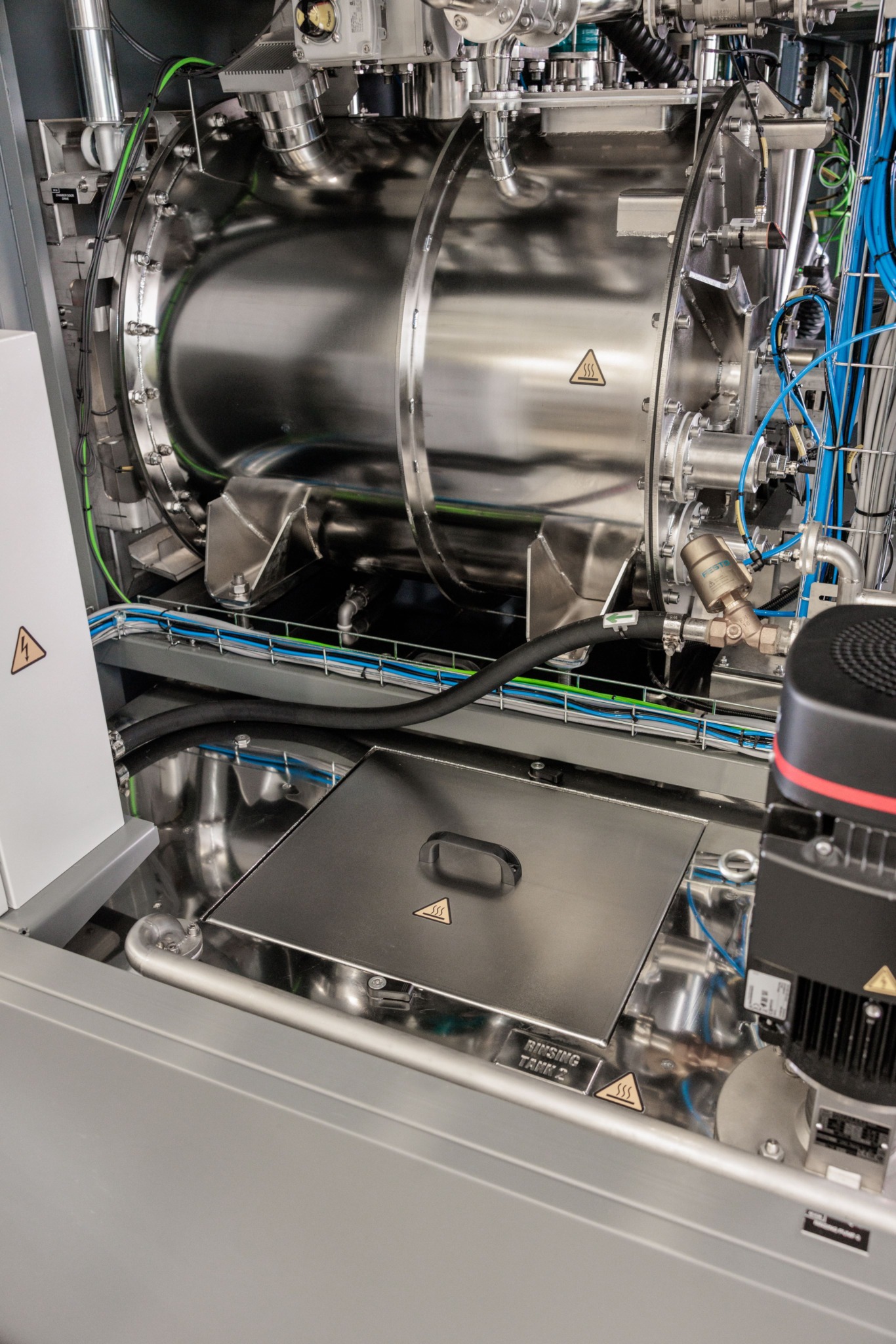

We offered the NOYEN Compact 200 cleaning machine in the CUSTOM version. The device allows the use of 3 technologies: spray, immersion and ultrasonic, which guarantees the highest quality results and allows carrying out different processes in one machine. The process consists of the following stages: cleaning, rinsing, hot air drying, vacuum drying, and cooling.

To our standard solution – the NOYEN Compact series machine – we have added a second rinsing tank, which allowed us to achieve the desired cleanliness. The medium flow system has been finished with an electropolish, ensuring that contaminants washed off the parts do not settle on the elements of the washing medium circulation system, thus extending the life of the washing bath. We have also implemented the PureSpray System, an advanced solution for precise and safe cleaning workpieces made of brittle materials.

As part of the selection of the industrial cleaning technology, we carried out a series of laboratory tests to match the appropriate chemical. We proposed NOYEN PAL – our proprietary low-foaming cleaning agent, which is an aqueous mixture of surfactants, organic and inorganic corrosion inhibitors and contains additives to neutralise water hardness.

- Washing device dimensions (mm): 2220 (L) x 2930 (W) x 2360 (H)

- Process basket dimensions (mm): 650 (L) x 470 (W) x 300 (H)

- Maximum load: approx. 100 kg

- Cycle time for basket cleaning: about 20 minutes

What did the client gain from working with NOYEN?

The customer chose to purchase a cleaning machine from NOYEN because of the comprehensive approach to the offered solution. We provided not only the device and modification of its equipment according to the customer’s needs, but also the selection of appropriate chemicals and technology, creating a holistic support in the washing process.

Other benefits:

- Compact device size

- Customisation of the standard NOYEN solution to the client’s individual needs

- Flexible solution for cleaning parts of various sizes

- Safe and precise cleaning of parts susceptible to mechanical damage

- Efficient cleaning process that meets quality requirements

- Reduced frequency of washing bath changes – minimized waste generated in the process

- Full technological selection and NOYEN support in the process

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.