Industrial cleaning of aircraft engine covers and components

Our client, a global leader in the design, manufacture and servicing of aircraft engines, came in for assistance with the industrial cleaning process. The customer needed to wash various types of aircraft engine covers and components made of titanium, magnesium alloy and aluminum parts.

What did the client require?

- Cleaning of aircraft engine cowlings and components from contaminants such as coolants and machining chips – intermediate or final washing

- A machine tailored to individual needs, while at the same time characterized by versatility

- A cleaning machine capable of both standard washing of components for further production process and washing in accordance with cleanliness standards, meeting washing standards up to 200 microns

Solution implemented at the client’s site

To meet the customer’s expectations, NOYEN experts proposed the NOYEN COMPACT 800 cleaning machine. The solution was tailored to meet any special customer requirements, such as the dimension of the process basket and its loading capacity.

Dimensions of the process basket: 800 x 800 x 600 mm

Workpiece loading: 200 kg

Machine dimensions: 4900 x 2500 x 3250 mm

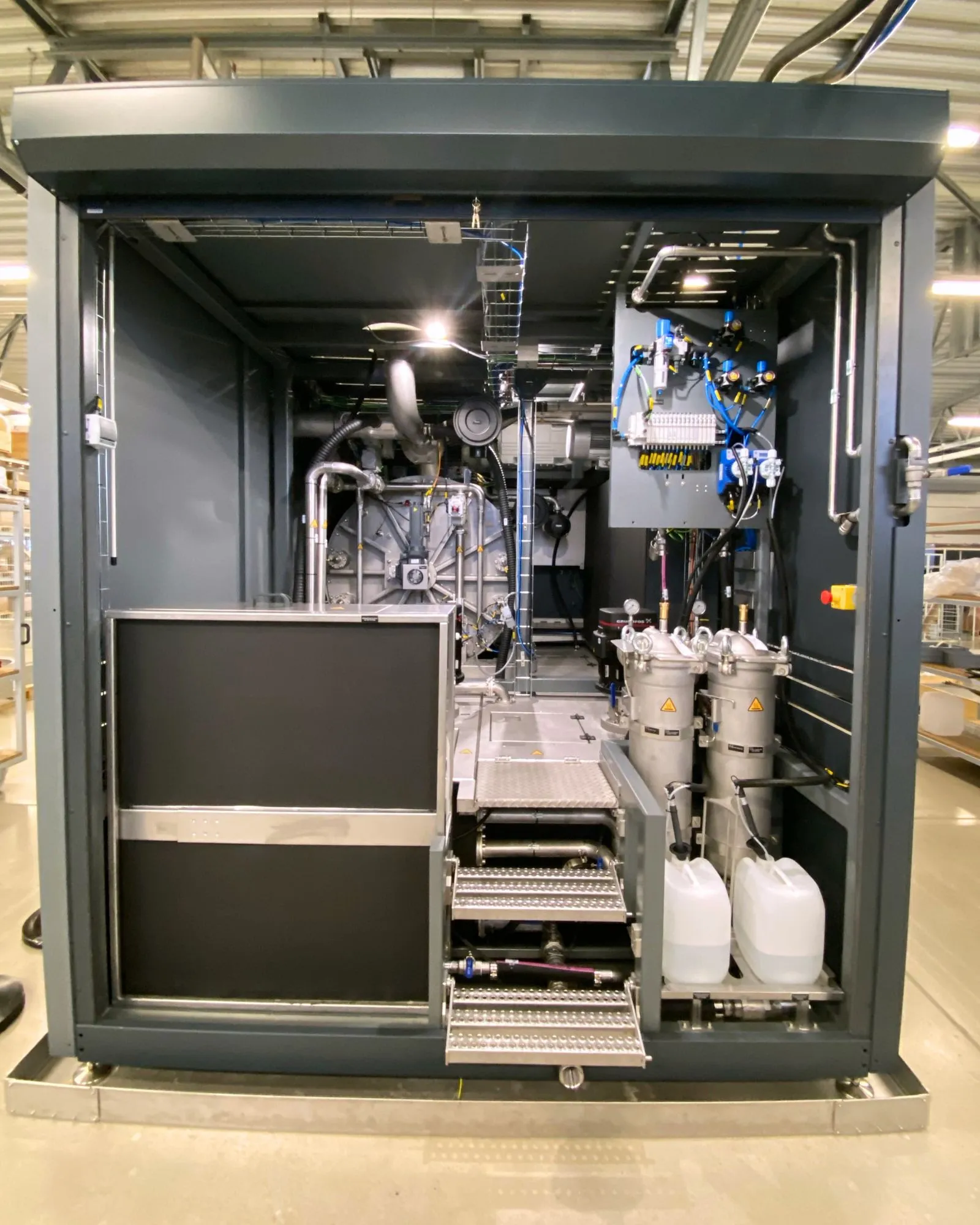

The cleaning process consists of the following stages: washing, rinsing, drying including vacuum drying. Device allows the use of up to 3 cleaning technologies: spray, immersion and ultrasonic, which guarantees the highest quality of the expected results. The use of servo drive gives the possibility to manipulate the rotation of the basket at the customer’s discretion. The cleaning machine effectively removes various types of contaminants even from parts with complex geometry.

In the vacuum drying process, all parts with complex geometries and hard-to-reach blind holes are dried efficiently. During vacuum drying, the temperature of the parts is also lowered, facilitating faster preparation for the next stages of the manufacturing process.

With the use of accurate filter cartridges and a top line filter housing, precise filtration of the washing and rinsing medium and separation of metallic particles is possible.

The efficiency and high quality of the process is guaranteed by the cylindrical shape of the chamber, which facilitates the rinsing of lingering particles, and ultrasonic transducers in the form of tubes, ensuring optimal ultrasonic distribution.

For the ergonomics of working with the cleaning device, the customer was offered an automatic loading platform for baskets with a buffer station. With the use of such a solution, it is possible for the operator to conveniently load workpieces in the basket without having to use force to lift the basket itself.

The baskets of the washer have been coated with plastic, which nullifies mechanical damage when the workpieces come into contact with the walls of the basket. In addition, such a solution works well when washing magnesium alloys, as it prevents discoloration in contact with stainless steel.

What did the client gain by working with NOYEN?

- Ability to wash various components, according to the cleanliness standard, up to 200 microns

- Versatility of application of the washer for various references

- Efficient drying of workpieces in hard-to-reach blind holes thanks to vacuum drying

- Compact size of the machine

- Appropriate selection of the device according to the customer’s requirements with constant contact with NOYEN’s engineering department during the design of the device

- Monitoring function of all process data on an easy-to-read HMI panel, ensuring safety and full control of the cleaning process – available in several languages

Distance is not a problem for us! At NOYEN, we fulfill orders with convenient delivery times even to another continent, taking care of safe transportation and service support.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.