Cleaning copper pipes after soldering for a heating technology manufacturer

Our client – a global manufacturer of heating technologies and a world-leading provider of efficient climate and renewable energy solutions – again asked us to assist in the industrial cleaning process. This time the order was for a rather unusual cleaning machine, designed specifically for the customer’s individual needs.

What did the client require?

- Cleaning machine designed for washing copper pipes of various shapes and diameters after the soldering process

- Reduction to a minimum of bath replacement time

- Easy access to filters and tanks – the ability to perform quick maintenance service

Solution implemented at the client’s site

Why is the solution designed specifically for the customer unusual?

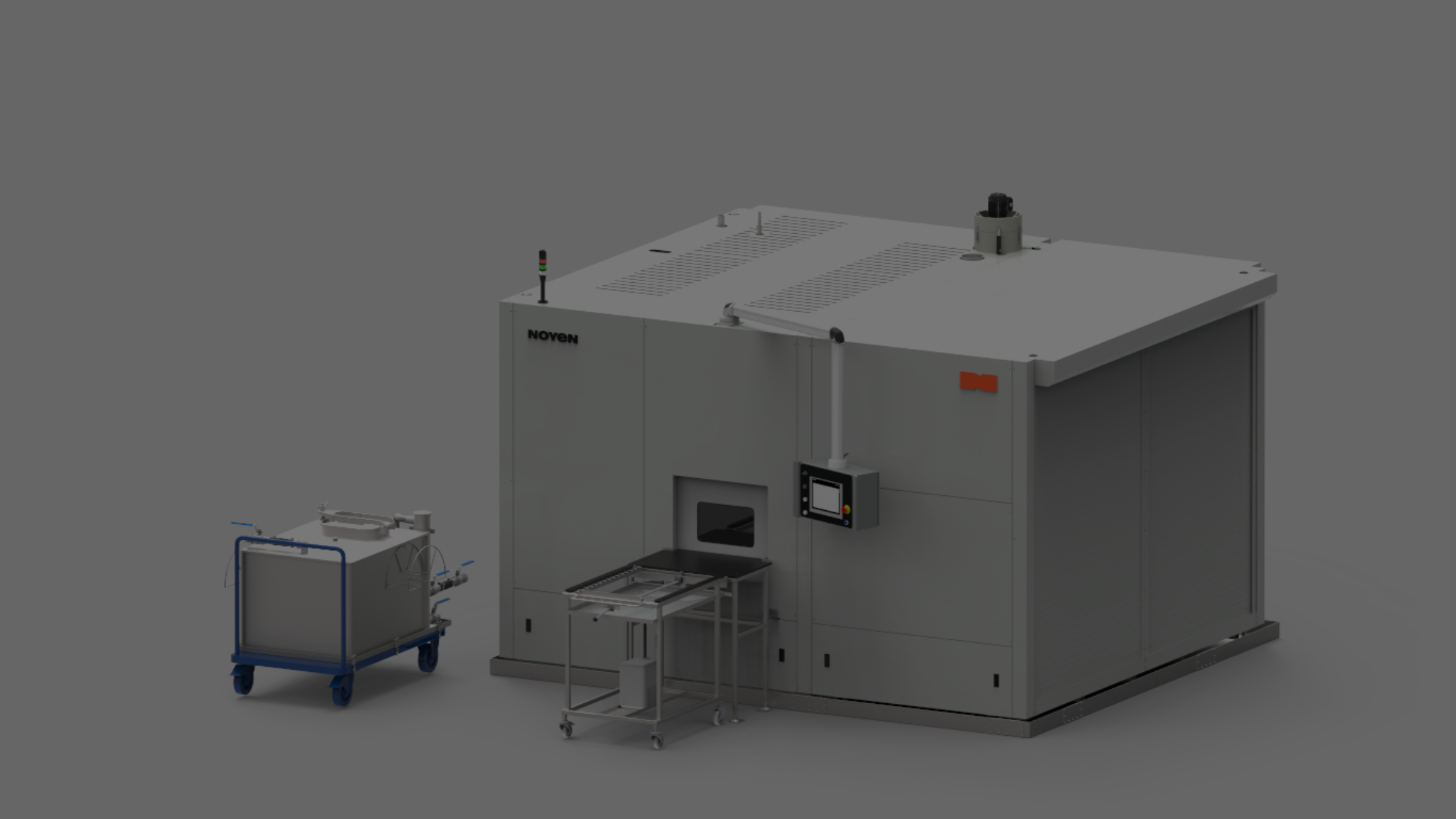

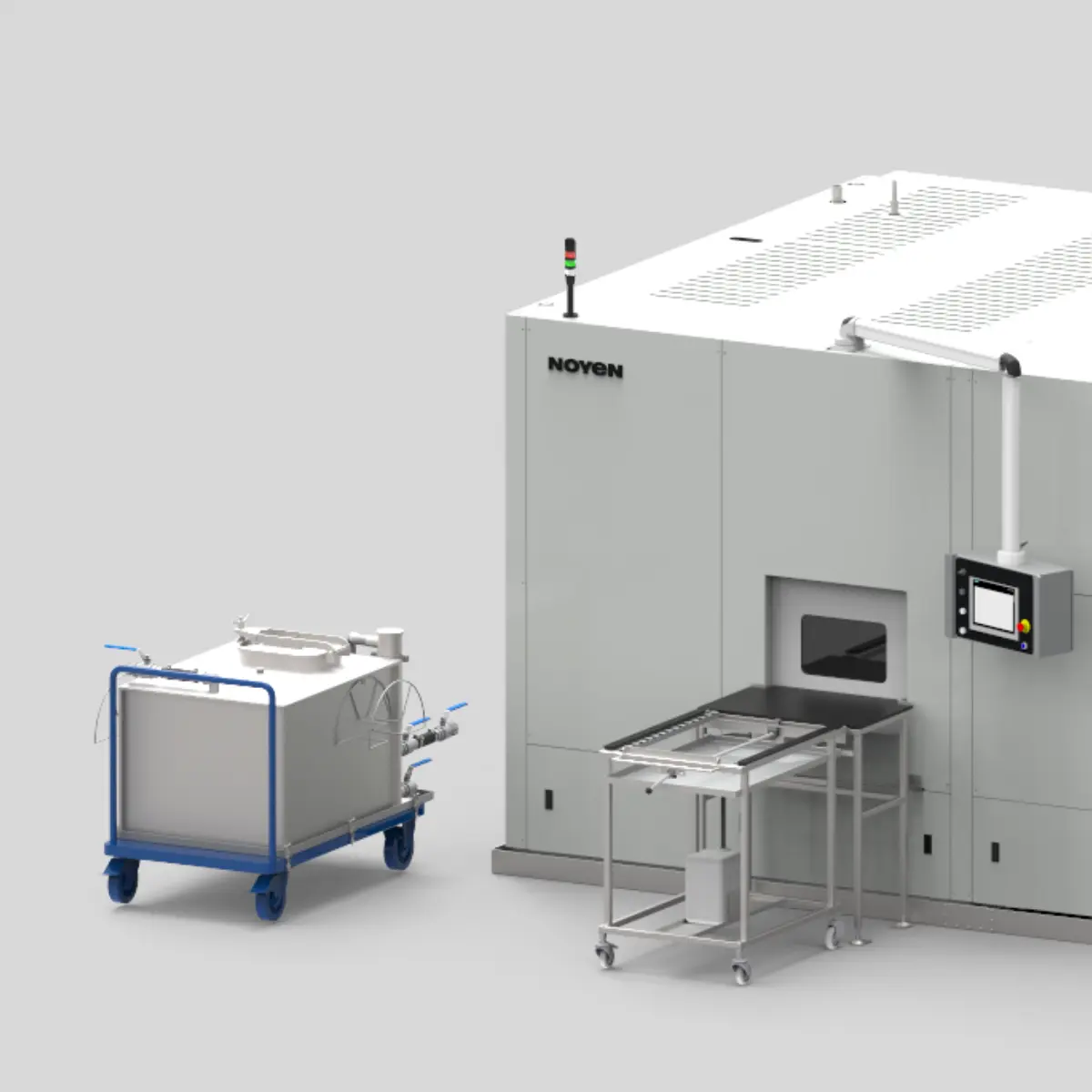

Because the industrial cleaning machine consists of two devices: the NOYEN EXPERT 600 WRD cleaning machine and an additional machine for washing process tubs.

This is a new solution, making it easier to keep the cleaning machine clean for longer. The use of the additional cleaning machine and the process liquid tub washing system makes it possible to reduce bath changeover time and the involvement of human resources. In addition, the expanded system of rapid emptying and filling of the baths, halves the time of preparing the cleaning device for operation.

The entire technology for industrial cleaning of workpieces in the device was developed by the Noyen laboratory and confirmed by a series of tests. It is based on chemical preparations produced at our headquarters.

The industrial cleaning process includes washing and etching of dirt, and rinsing in our new chemical preparation NOYEN KP. The benefits of using this particular formulation are improved wettability, prevention of discoloration on the material and sedimentation, but also a visual effect, due to the formulation’s effect of highlighting the red color of copper.

Another advantage of the NOYEN EXPERT 600 WRD is the process chamber’s ability to wash short and medium parts in two baskets simultaneously. On the other hand, for longer length parts, the possibility of using one long process basket.

Depending on the reference being washed, the process time varies from 12 to 18 minutes.

What did the client gain by working with NOYEN?

- Involvement of fewer employees for chemical service

- Reduction of bath replacement time in the machine to a minimum

- Possibility of washing in one or two smaller baskets – depending on the length of workpieces

- Increased efficiency in washing short and medium workpieces

- Possibility of washing long details in the same machine

- Technical support of technologists, service

- Chemical care during the cleaning process – research and tests

NOYEN EXPERT 600 WRD can also be used by other manufacturers of heat exchangers and companies in the heating industry, which have in their production process degreasing after the formation of copper components and elimination of impurities after the soldering process. At NOYEN, each machine is designed to meet even the highest customer requirements. We customize cleaning machines to meet individual needs, creating more and more interesting and unusual solutions in the process. Thanks to our own laboratory, at NOYEN we carefully lay out each washing process along with the selection of chemical preparations of our own production.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.